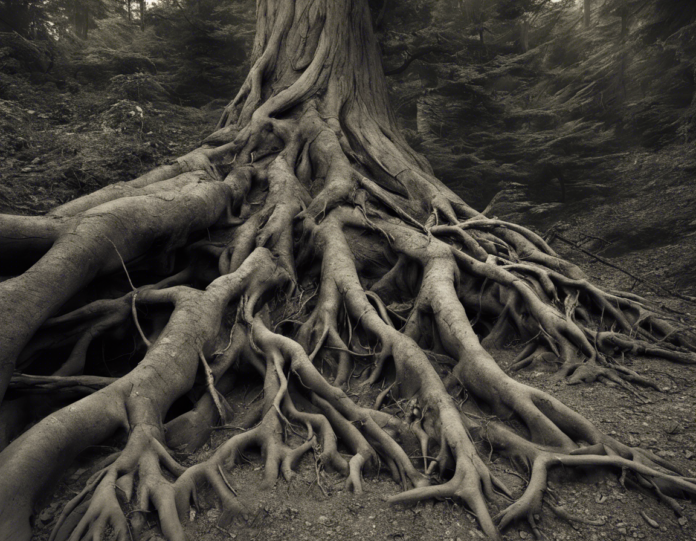

In the realm of problem-solving methodologies, Root Cause Analysis (RCA) stands out as a systematic approach to identifying the underlying causes of issues or incidents. This widely-used technique focuses on addressing the root cause of a problem instead of just treating its symptoms, thus preventing its recurrence in the future. One of the notable strategies within the RCA framework is known as Brute Force Analysis. In this article, we delve into the world of Root Cause Analysis, specifically exploring the Brute Force approach, its application, benefits, and how it stands out among other RCA methods.

Understanding Root Cause Analysis

Root Cause Analysis is a problem-solving technique employed across various industries such as manufacturing, healthcare, information technology, and beyond. It emphasizes the need to dig deeper into the cause-and-effect relationships surrounding an issue, aiming to get to the bottom of what actually triggered the problem in the first place. By leveraging RCA, organizations can move away from quick fixes and temporary solutions, propelling them towards sustainable problem resolution.

The Process of Root Cause Analysis

RCA typically involves the following steps:

- Identifying the Problem: Understanding and clearly defining the issue at hand.

- Data Collection: Gathering relevant data and information related to the problem.

- Root Cause Identification: Determining the underlying cause(s) of the problem.

- Solution Implementation: Developing and executing corrective actions to address the root cause.

- Follow-up and Monitoring: Ensuring that the implemented solutions are effective and sustainable.

Introducing Brute Force Analysis

Brute Force Analysis is an intensive and focused approach within the Root Cause Analysis methodology aimed at leaving no stone unturned when identifying the root cause of a problem. As the name suggests, this method involves a systematic and exhaustive examination of all potential causes, eliminating them one by one until the true root cause is pinpointed. While this approach may require more time and resources compared to other RCA techniques, its thoroughness often leads to more accurate and sustainable solutions.

Key Characteristics of Brute Force Analysis

- Comprehensive Investigation: Brute Force Analysis delves into all conceivable causes, even those that may seem unlikely at first glance.

- Iterative Process: The analysis continues iteratively, eliminating possible causes until the true root cause is revealed.

- Detail-Oriented: Attention is given to the smallest details and factors that could contribute to the problem.

- In-depth Documentation: Detailed documentation of the analysis process and findings is crucial for clarity and future reference.

Benefits of Brute Force Analysis

1. Enhanced Accuracy: By considering a wide range of potential causes, Brute Force Analysis helps in identifying the actual root cause with a higher degree of accuracy.

2. Prevention of Recurrence: By addressing the fundamental cause of the problem, Brute Force Analysis reduces the likelihood of the issue recurring in the future.

3. Improved Decision Making: The insights gained from a thorough Brute Force Analysis empower organizations to make informed decisions regarding problem resolution and prevention strategies.

4. Long-term Cost Savings: While Brute Force Analysis may require more resources upfront, the long-term benefits of preventing recurring issues often outweigh the initial investment.

Contrasting Brute Force Analysis with Other RCA Methods

Fishbone Diagram (Ishikawa Diagram)

- Focus: While the Fishbone Diagram is effective for identifying potential causes, it may not delve as deeply into each cause as Brute Force Analysis.

5 Whys Analysis

- Depth of Analysis: The 5 Whys technique focuses on asking “why” iteratively to uncover root causes, but it may not explore as many potential causes as Brute Force Analysis.

The Brute Force Approach in Action

To illustrate the Brute Force Analysis method, consider a manufacturing scenario where a company experiences a sudden increase in product defects. While other RCA methods might lead to identifying surface-level causes like machinery malfunction, a Brute Force Analysis would dive deeper. It would scrutinize variables such as raw materials, production procedures, environmental factors, employee training, and more until the actual root cause is discovered – perhaps a supplier change leading to substandard materials.

FAQs: Unraveling the Complexity of Root Cause Analysis

1. What are the common challenges faced during Root Cause Analysis?

Common challenges include overlooking interconnected causes, relying on assumptions instead of data, time constraints leading to hasty conclusions, and organizational resistance to change based on RCA findings.

2. Is Root Cause Analysis a one-time process, or should it be repeated periodically?

RCA should ideally be an ongoing process, continuously reevaluated based on new data and feedback to prevent recurring issues.

3. How can organizations ensure effective implementation of RCA findings?

Effective implementation involves clear communication of findings, engaging stakeholders in the solution process, setting measurable objectives, and monitoring progress consistently.

4. Are there software tools available to aid in Root Cause Analysis?

Yes, there are various software solutions designed to streamline the RCA process, allowing for data collection, analysis, and documentation in a centralized platform.

5. What role does leadership play in fostering a culture of Root Cause Analysis within an organization?

Leadership is instrumental in championing a proactive problem-solving culture, encouraging open communication, allocating resources for RCA initiatives, and fostering a learning mindset regarding failures.

Conclusion

In conclusion, Root Cause Analysis serves as a critical tool for organizations seeking to address underlying issues systematically and prevent their recurrence. Within the RCA framework, the Brute Force Analysis approach stands out for its thoroughness and exhaustive examination of potential causes, ultimately leading to more precise and sustainable solutions. By embracing the principles of Root Cause Analysis, organizations can pave the way towards continuous improvement, enhanced problem-solving capabilities, and a culture focused on sustainable success.